Products

Magnesium Oxide Ceramics for Crucible

Features

The magnesium oxide is used as a refractory under severe conditions because its melting point (3099K) is the highest in the oxide. The magnesium oxide is superior in corrosion resistance in the molten metal. Magnesium oxide can be used for a lot of metals compared with aluminum oxide.

High densification

This product has a high densification quality due to the addition of yttrium oxide.

Inexpensive

We offer affordable prices.

Usage

Crucibles for metal melting

Tools for Sintering Ceramics.

Alternatives to Aluminum Oxide Ceramics

These products can be used for heat treatment of nickel alloys, plutonium/uranium refining, superconductor materials, piezoelectric materials, and lead materials.

They can be used in high temperature environments up to 2200°C.

Chemical Composition(Typical)

All slip cast products are manufactured from high purity fused magnesium oxide grain. A direct substitution of up to 2% Y2O3 is made at the expense of MgO.

TYPICAL ANALYSIS BELOW:

| CONTENT | Typical |

|---|---|

| MgO + Y2O3 | 98.5% |

| CaO | 0.5% |

| SiO2 | 0.1% |

| Al2O3 | 0.55% |

| Fe2O3 | 0.06% |

| B2O3 | <0.002% |

Physical Properties (Typical)

| Category | Value |

|---|---|

| Bulk density (103kg・m-3) | 3.44 |

| Apparent porosity (%) | 0.10 |

| Water absorption (%) | 0.03 |

| Three point bending strength (MPa) | 123 |

| Thermal expansion coefficient (10‑6 K‑1) | 13.9 |

| Thermal conductivity (W·m‑1·K‑1) | 46.3 |

| Specific heat (J·kg‑1·K‑1) | 990 |

Size and Surface

| CONTENT | Typical |

|---|---|

| Dimensions | The normal fabrication range is for diameters less than 6 inches and lengths less than 12 inches. Larger parts can be made upon request, at some sacrifice in cost and dimensional control. Please inquire for further information. |

| Wall thickness | The nominal wall thickness for most shapes is 0.125” (or 3mm), and the maximum thickness available is limited to 0.16 inch (4mm). |

| Surface | Surface finish may vary, but is usually smooth. Surface is not usually “vitrified”. |

| Tolerances | All dimensions are outside dimensions and may vary +/- 5%. Nominal wall is lesser of 5% of diameter or .125 inch. Some warping and sidewall distortion is normal for MgO, especially rectangular shapes. Nominally flat surfaces may be slightly convex or concave. All tray Heights are hand finished and may vary by 25%. |

Shape

Parts are made by slip casting. Slip casting is suitable for production of hollow shapes with uniform wall thickness and an opening to the interior. This is ideal for shapes such as crucibles, trays, boats, etc. There should be no re-entrant angles along the longitudinal cross section of the part (such as Ell-shapes, Crosses, etc.).

Slip casting will produce a variety of shapes as indicated above. Surface finish does not approximate that of machined surfaces. Nominally flat surfaces, such as lids, crucible and tray bottoms, and plates will be concave or convex after firing. If precision dimensions or flat surfaces are required, additional wet diamond machining is required, and many limitations apply.

Custom shapes will require set-up charges and sufficient lead time for mold master and mold production.

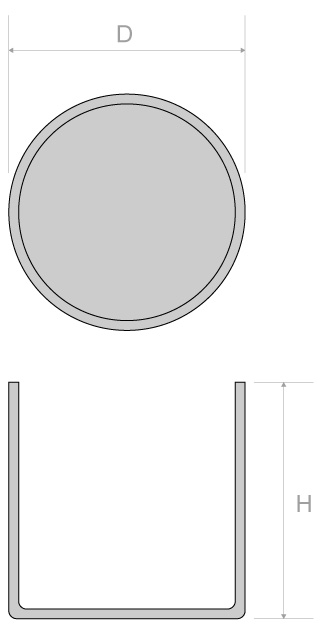

FLAT BOTTOMED CRUCIBLES

| Item Name | Diameter (D) | Height (H) | Weight | Interior Vol. | ||

|---|---|---|---|---|---|---|

| Unit | inch | mm | inch | mm | g | cc |

| SC02402 | 0.24 | 6 | 0.20 | 5 | 0.3 | 0.05 |

| SC04008 | 0.40 | 10 | 0.79 | 20 | 4 | 0.5 |

| SC05010 | 0.50 | 13 | 1.00 | 25 | 8 | 1 |

| SC07116 | 0.71 | 18 | 1.57 | 40 | 18 | 5 |

| SC07510 | 0.75 | 19 | 1.00 | 25 | 13 | 4 |

| SC10010 | 1.00 | 25 | 1.00 | 25 | 19 | 7 |

| SC10012 | 1.00 | 25 | 1.25 | 32 | 23 | 9 |

| SC10030 | 1.00 | 25 | 3.00 | 76 | 51 | 24 |

| SC12512 | 1.25 | 32 | 1.25 | 32 | 36 | 15 |

| SC12520 | 1.25 | 32 | 2.00 | 51 | 54 | 25 |

| SC12525 | 1.25 | 32 | 2.50 | 64 | 66 | 31 |

| SC12560 | 1.25 | 32 | 6.00 | 152 | 150 | 77 |

| SC15020 | 1.50 | 38 | 2.00 | 51 | 67 | 38 |

| SC15030 | 1.50 | 38 | 3.00 | 76 | 97 | 59 |

| SC17525 | 1.75 | 44 | 2.50 | 64 | 99 | 70 |

| SC17535 | 1.75 | 44 | 3.50 | 89 | 134 | 99 |

| SC20020 | 2.00 | 51 | 2.00 | 51 | 97 | 75 |

| SC20035 | 2.00 | 51 | 3.50 | 89 | 157 | 135 |

| SC20050 | 2.00 | 51 | 5.00 | 127 | 217 | 195 |

| SC20060 | 2.00 | 51 | 6.00 | 152 | 257 | 234 |

| SC22535 | 2.25 | 57 | 3.50 | 89 | 180 | 176 |

| SC25030 | 2.50 | 64 | 3.00 | 76 | 179 | 189 |

| SC25055 | 2.50 | 64 | 5.50 | 140 | 306 | 354 |

| SC27535 | 2.75 | 70 | 3.50 | 89 | 265 | 264 |

| SC30030 | 3.00 | 76 | 3.00 | 76 | 259 | 272 |

| SC30040 | 3.00 | 76 | 4.00 | 102 | 330 | 368 |

| SC30057 | 3.00 | 76 | 5.75 | 146 | 455 | 534 |

| SC35060 | 3.50 | 89 | 6.00 | 152 | 566 | 782 |

| SC40045 | 4.00 | 102 | 4.50 | 114 | 518 | 777 |

| SC40060 | 4.00 | 102 | 6.00 | 152 | 662 | 1044 |

| SC45060 | 4.50 | 114 | 6.00 | 152 | 761 | 1343 |

| SC50050 | 5.00 | 127 | 5.00 | 127 | 743 | 1394 |

| SC50080 | 5.00 | 127 | 8.00 | 203 | 1105 | 2254 |

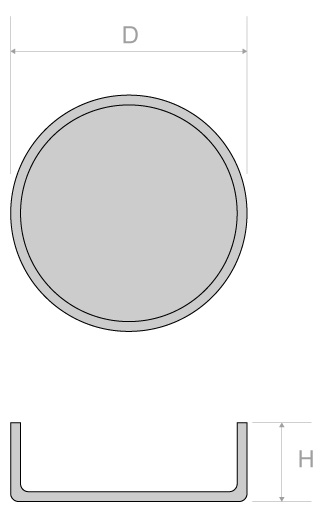

ROUND TRAYS

| Item Name | Diameter (D) | Height (H) | Weight | Interior Vol. | ||

|---|---|---|---|---|---|---|

| Unit | inch | mm | inch | mm | g | cc |

| SR1005 | 1.00 | 25 | 0.50 | 13 | 11 | 3 |

| SR2005 | 2.00 | 51 | 0.50 | 13 | 37 | 15 |

| SR2010 | 2.00 | 51 | 1.00 | 25 | 57 | 35 |

| SR3005 | 3.00 | 76 | 0.50 | 13 | 82 | 34 |

| SR3010 | 3.00 | 76 | 1.00 | 25 | 117 | 82 |

| SR4005 | 4.00 | 102 | 0.50 | 13 | 134 | 64 |

| SR4010 | 4.00 | 102 | 1.00 | 25 | 182 | 153 |

| SR6010 | 6.00 | 152 | 1.00 | 25 | 395 | 349 |

| SR6012 | 6.00 | 152 | 1.25 | 32 | 437 | 453 |

RECTANGULAR TRAYS

| Item Name | Width (W) | Length (L) | Height (H) | Weight | |||

|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | inch | mm | g | |

| ST104005 | 1.00 | 25 | 4.00 | 102 | 0.50 | 13 | 44 |

| ST106005 | 1.00 | 25 | 6.00 | 152 | 0.50 | 13 | 65 |

| ST202005 | 2.00 | 51 | 2.00 | 51 | 0.50 | 13 | 47 |

| ST203005 | 2.00 | 51 | 3.00 | 76 | 0.50 | 13 | 74 |

| ST204005 | 2.00 | 51 | 4.00 | 102 | 0.50 | 13 | 96 |

| ST254005 | 2.50 | 64 | 4.00 | 102 | 0.50 | 13 | 115 |

| ST254010 | 2.50 | 64 | 4.00 | 102 | 1.00 | 25 | 164 |

| ST256010 | 2.50 | 64 | 6.00 | 152 | 1.00 | 25 | 231 |

| ST306010 | 3.00 | 76 | 6.00 | 152 | 1.00 | 25 | 261 |

| ST356010 | 3.50 | 89 | 6.00 | 152 | 1.00 | 25 | 329 |

| ST404010 | 4.00 | 102 | 4.00 | 102 | 1.00 | 25 | 232 |

| ST406010 | 4.00 | 102 | 6.00 | 152 | 1.00 | 25 | 364 |

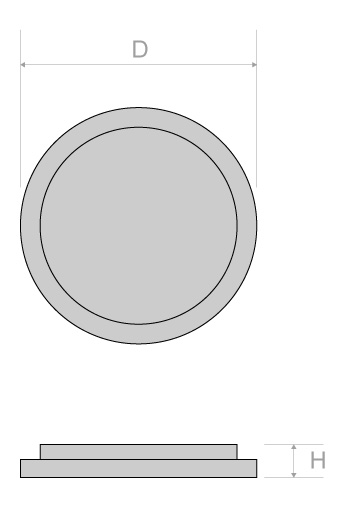

FLANGED LIDS

| Item Name | Diameter (D) | Height (H) | Weight | ||

|---|---|---|---|---|---|

| Unit | inch | mm | inch | mm | g |

| SF100 | 1.00 | 25 | 0.2 | 5 | 10 |

| SF125 | 1.25 | 32 | 0.2 | 5 | 14 |

| SF150 | 1.50 | 38 | 0.2 | 5 | 21 |

| SF200 | 2.00 | 51 | 0.2 | 5 | 35 |

| SF250 | 2.50 | 64 | 0.2 | 5 | 55 |

| SF300 | 3.00 | 76 | 0.2 | 5 | 79 |

| SF400 | 4.00 | 102 | 0.2 | 5 | 141 |

| SF450 | 4.50 | 114 | 0.2 | 5 | 179 |

| SF500 | 5.00 | 127 | 0.2 | 5 | 221 |

| SF700 | 7.00 | 178 | 0.2 | 5 | 435 |

*Export Control Statement - These items are controlled by the U.S. Government and authorized for export only to the country of ultimate destination for use by the ultimate consignee or end-user(s) herein identified. They may not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U.S. government or as otherwise authorized by U.S. law and regulations.

PRODUCT LIST

- Magnesium Oxide Ceramics for Crucible

- Aluminum Oxide Ceramics for Crucible

- Magnesium Oxide Ceramics for Insulator

- High Density Magnesium Oxide Ceramics (GRADE HRM)

- Aluminum Oxide Ceramics for Insulator

- Hafnium Oxide Ceramics for Insulator

- Silicon Dioxide Ceramics for Insulator

- Magnesium Aluminate Ceramics for Insulator

- Magnesium Oxide Powder

- Aluminum Oxide Powder

- Hafnium Oxide Powder

- Magnesium Oxide Ceramics for Setter